Continuous casting was originally developed in Europe after World War II as an alternative method of producing cast iron bar stock without patterns and conventional molding methods. A water-cooled graphite die which is mounted onto a holding crucible, is machined to form the shape of the bar. As the bar is pulled horizontally from the crucible, the ferrostatic head pressure feeds the molten iron core, producing a fine-grained cast iron. The core is still molten iron while the out skin goes to solid when it exits the die. The entire bar cools in air until it is notched and broken off in standard lengths. The rim has a finer graphite structure in a matrix which is more ferritic than that in the center. The most notable characteristic of continuous cast iron is its fine-grained, dense, as-cast microstructure. Since the bar is pulled from the bottom of the holding crucible, dross, slag and other impurities float to the top, away from the opening of the die.

|

›› Corrosion Resistance |

›› Surface finish |

|

›› Fatigue Strength |

›› Thermal Conductivity |

|

›› Hardness |

›› Vibration Damping |

|

›› Heat Treat Response |

›› Wear Resistance |

|

›› Machinability |

›› Weight Reduction |

|

›› Reduced Scrap |

|

|

Mechanical properties |

|

|||||||||||||||||

|

|

Hardness range: HB120-200 Result from R/2. There is difference from core to edge. |

|||||||||||||||||

|

Chemical composition |

Chemical composition only for reference |

|||||||||||||||||

|

Note: |

Mechanical properties is gotten from test bar. Test bar is taken from iron bar itself, in the middle of radius of iron bar. |

|

Mechanical properties |

|

|||||||||||||||||

|

|

Hardness range: HB160-240 Result from R/2. |

|||||||||||||||||

|

Chemical composition |

Chemical composition only for reference |

|||||||||||||||||

|

Note: |

Mechanical properties is gotten from test bar. Test bar is taken from iron bar itself, in the middle of radius of iron bar. |

|

Mechanical properties |

|

|||||||||||||||||

|

|

Hardness range: HB190-260 Result from R/2. |

|||||||||||||||||

|

Chemical composition |

Chemical composition only for reference |

|||||||||||||||||

|

Note: |

Mechanical properties is gotten from test bar. Test bar is taken from iron bar itself, in the middle of radius of iron bar. |

|

Mechanical properties |

|

||||||||||||||||||

|

Microstructure |

Type Ⅰ&Ⅱ nodular

graphite. |

||||||||||||||||||

|

Chemical composition |

Chemical composition only for reference |

||||||||||||||||||

|

Note: |

Mechanical properties is gotten from test bar. Test bar is taken from iron bar itself, in the middle of radius of iron bar. Heat treatment if needed, please kingly inform. |

|

Mechanical properties |

|

|||||||||||||||||

|

Microstructure |

Type Ⅰ&Ⅱ nodular

graphite. |

|||||||||||||||||

|

Chemical composition |

Chemical composition only for reference |

|||||||||||||||||

|

Note: |

Mechanical properties is gotten from test bar. Test bar is taken from iron bar itself, in the middle of radius of iron bar. Heat treatment if needed, please kingly inform. |

|

Mechanical properties |

|

|||||||||||||||||||

|

Microstructure |

Type Ⅰ&Ⅱ nodular

graphite. |

|||||||||||||||||||

|

Chemical composition |

Chemical composition only for reference |

|||||||||||||||||||

|

Note: |

The Mechanical properties are gotten from test bar. Test bar is taken from iron bar itself, in the middle of radius of iron bar. |

|

Mechanical properties |

|

||||||||||||||||||

|

Microstructure |

Type Ⅰ&Ⅱ nodular

graphite. |

||||||||||||||||||

|

Chemical composition |

Chemical composition only for reference |

||||||||||||||||||

|

Note: |

Mechanical properties is gotten from test bar. Test bar is taken from iron bar itself, in the middle of radius of iron bar. |

|

GRADE |

RELEVANT STANDARD |

||

|

Cast Bar 200 |

ISO 200 |

EN-GJL-200C |

ASTM A48 CLASS 30 |

|

Cast Bar 250 |

ISO 250 |

EN-GJL-250C |

ASTM A48 CLASS 35 |

|

Cast Bar 300 |

ISO 300 |

EN-GJL-300C |

ASTM A48 CLASS 45 |

|

Cast Bar 400-15 |

ISO 400-15 |

EN-GJS-400-15C |

|

|

Cast Bar 450-12 |

ISO 450-12 |

EN-GJS-450-12C |

ASTM A536 CLASS 65-45-12 |

|

Cast Bar 500-7 |

ISO 500-7 |

EN-GJS-500-7C |

ASTM A536 CLASS 80-55-06 |

|

Cast Bar 600-3 |

ISO 600-3 |

EN-GJS-600-3C |

ASTM A536 CLASS 80-60-03 |

|

Grey Iron |

|

|

Ductile Iron |

|

|

|

Outer

dia. 310mm |

|

|

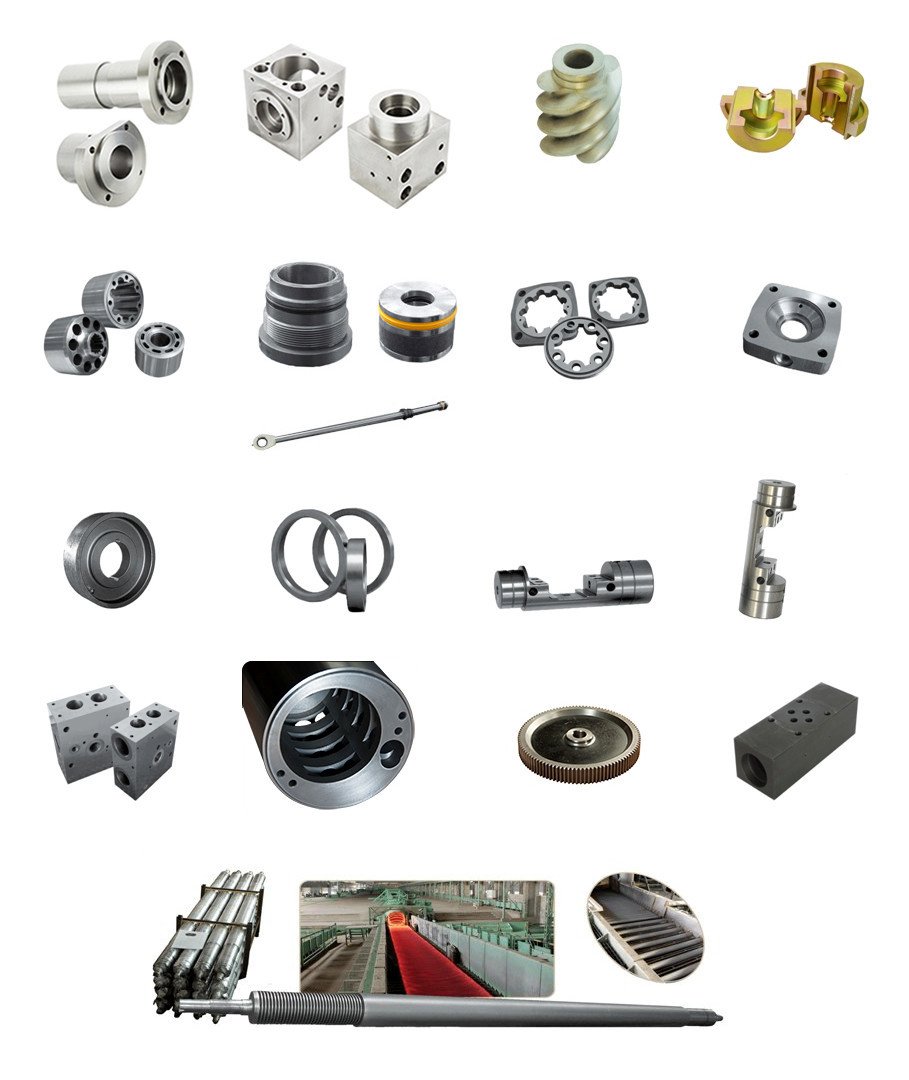

Oil and air pressure equipment

|

Valves |

Stack valve, Modular valves, Relief valve, Flow control valve, Solenoid valve, Sub plate, Manifold |

|

Cylinders |

Piston , Head cover, Rod cover , Cushion ring |

|

Others |

Pulley and Boss for blower, Rotor, Impeller Liner Flange for compressor |

Machine tools and general industrial machineries

|

Metal machine tools |

Stack valve, Modular valves, Relief valve, Flow control valve, Solenoid valve, Sub plate, Manifold |

|

Injection molding machines |

Valve, Manifold, Cylinder, Mounting plate at fixed side, Mounting plate at moving side, Ejector plate, Spacer block |

|

Civil engineering and construction machines |

Valve, Cylinder piston, Manifold |

|

Printing machines |

Ink mixing roller, Ink rail, Guide, Gear |

|

Spinning machines |

Bearing case,Gear, Weight, Rail, Top roller, Guide tube, Bearing, Cross slide, Bearing holder, Slide base, Bushing, Cam of sewing machine |

|

Agricultural machines |

Piston head, Head cover, Pulley for tractor, Pulley Bushing for combine |

|

Others |

Parts for Package of paper, Food processing, wood-working machine |

Automobiles, transportation equipment

|

Automobiles |

Shock absorber, Valve guide, Mechanical seal, Collar, Bushing, Weight, Speed meter gear sleeve, Mechanical seal Spacer for cooler |

|

Cranes and Ships |

Manifold, Cylinder, Piston, Valve guide, Engine, Engineering valve stem bushing, cylinder block |

|

Cranes |

Sheave, Collar, Bushing, Wheel |

|

Others |

Winch drum, Elevator hook, Weight, Conveyor roller |

Electrical equipment and tools

|

Compressor roller for rotary air conditioner, Spider, Slider, Cross slide pin, Facsimile vacuum pump, Motor gear, Rotor for cooler, Disc brake of generator |

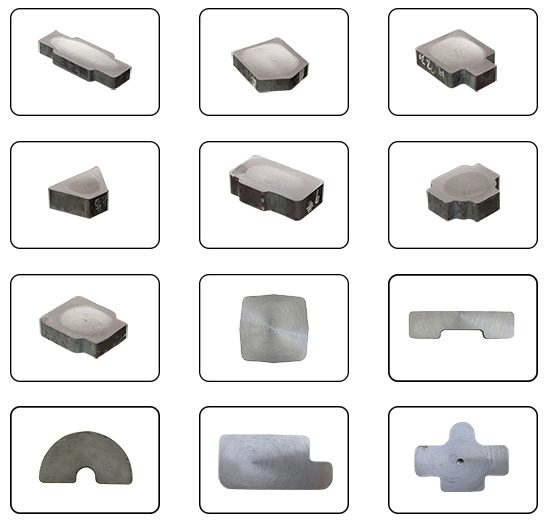

Metal molds

|

For glass, for aluminum die casting, for plastics, for grinding wheel, for pen points, for pressure casting, for lens polishing, for analyzing pieces for shell molding and cold box process |

Pumps

|

Gear of gear-pump, Rotor of screw pump, Shaft Seal, Rotor, Flange, Flow control, Check valve, Yoke sleeve, valve guide for chemical pump |

General universal parts

|

Gear, Pulley, Sheave, Bearing, Shaft, Bushing, Collar, Cam, Coupling, Flange, Boss, Weight, Casing, Pin rail, Cases and covers, Seal, Rotor, Base, Ring, Roller, Nut, Plate, Plug, Block, Score, jig and tools

|